Portability Solutions

Better portability, improved security, lower safety issues, fully factory tested, reduced installation time, plug-and-play solutions.

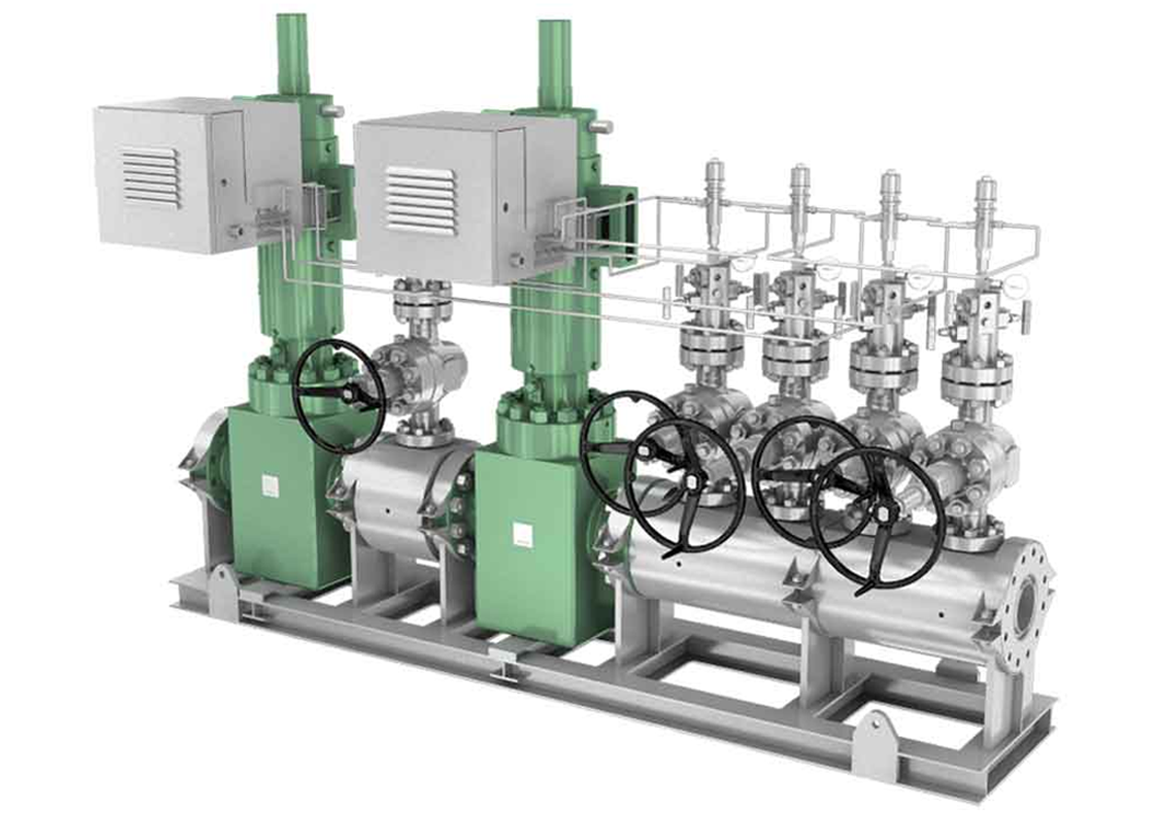

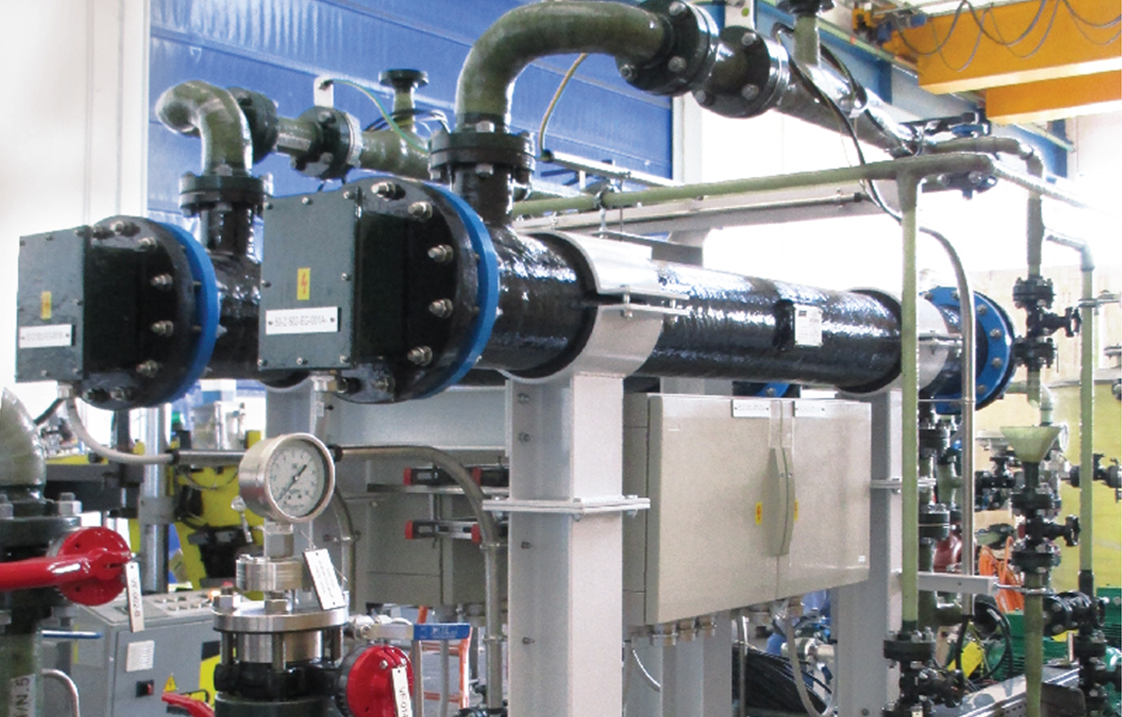

Package Engineering

Process engineering mastered and built as packaged solutions to specific client requirements with stringent quality and certification.