Process Systems

Expertise in oil processing, gas processing and water treatment

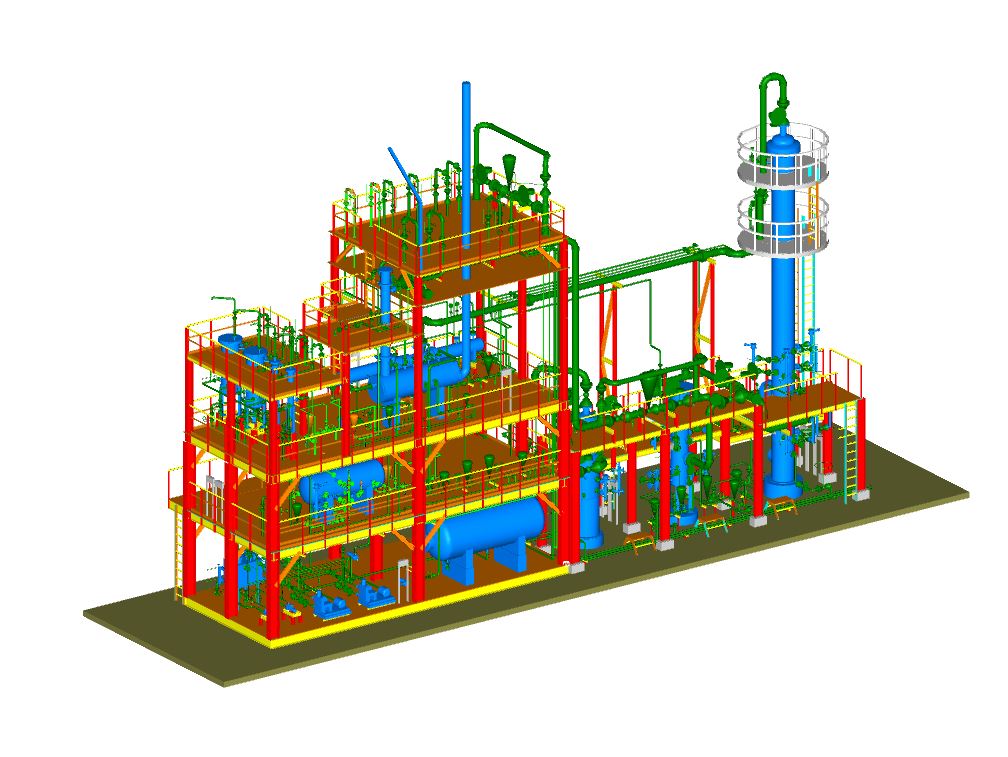

Bespoke Systems & Services

Engineering, procurement, packaging, construction, testing and commissioning of bespoke solutions.

Expertise in oil processing, gas processing and water treatment

Engineering, procurement, packaging, construction, testing and commissioning of bespoke solutions.

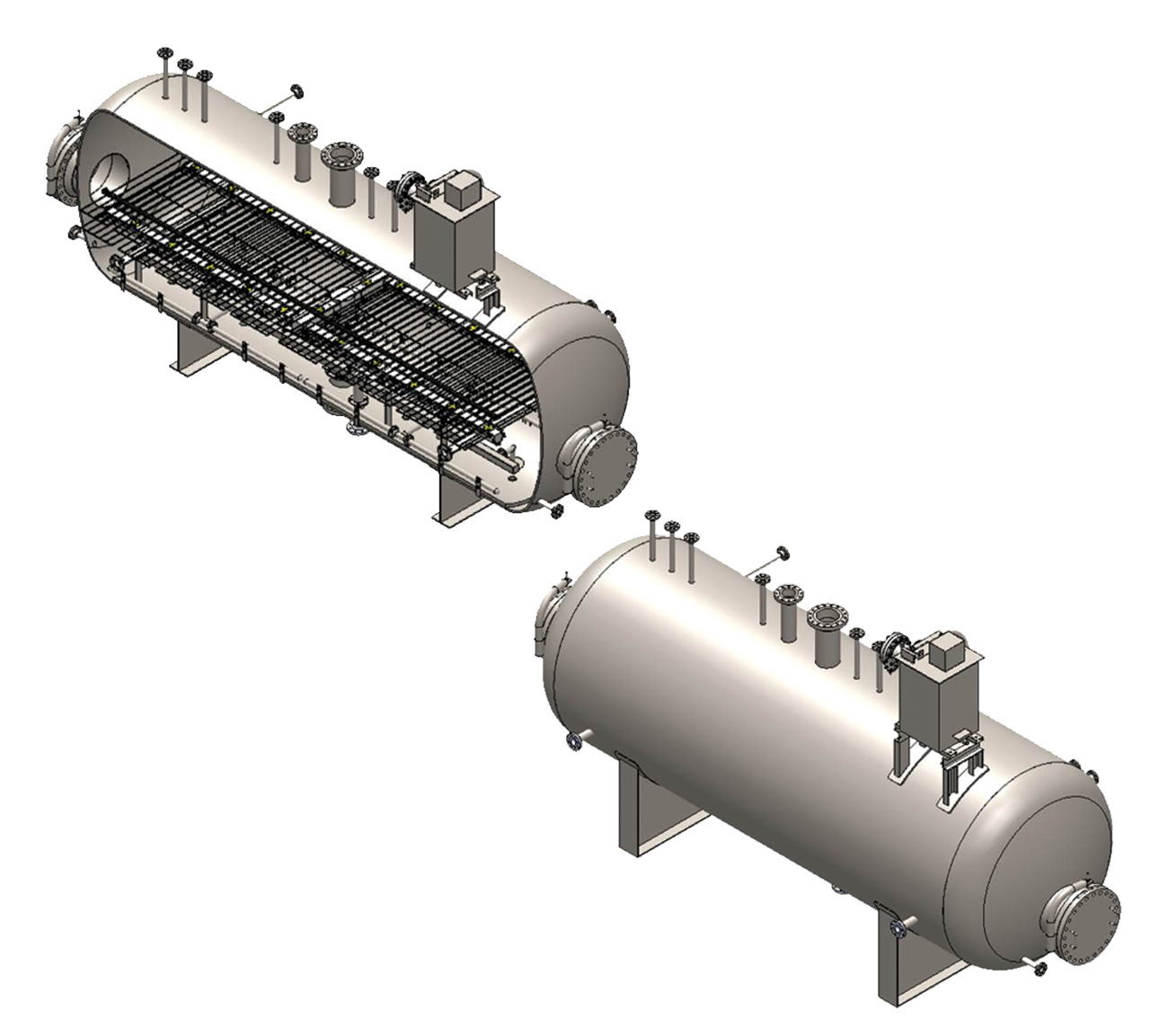

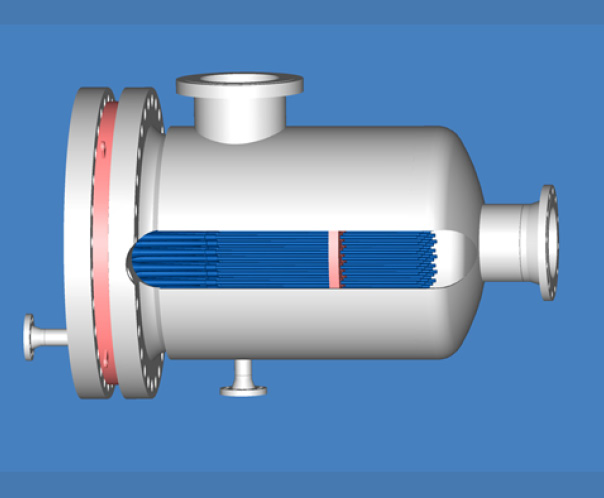

Technomak provides a wide range of separation internals, which are compact and efficient for gas/liquid/solid separation.

The offerings include conventional internals as well as custom-designed internals for special applications using CFD and empirical model. The applications include the following:

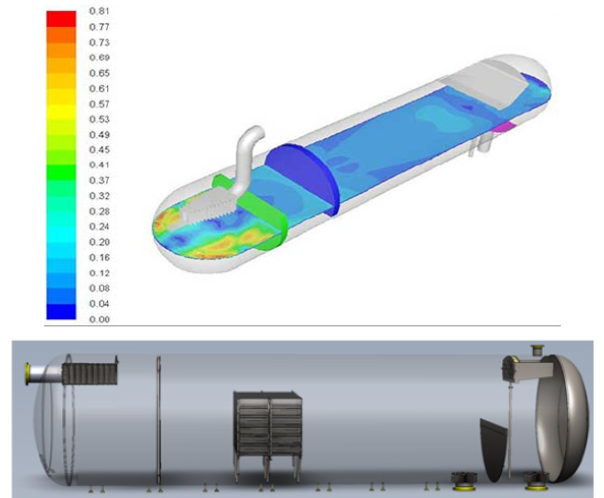

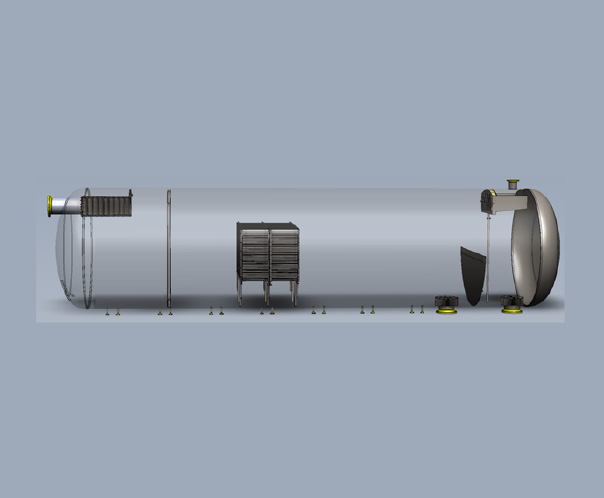

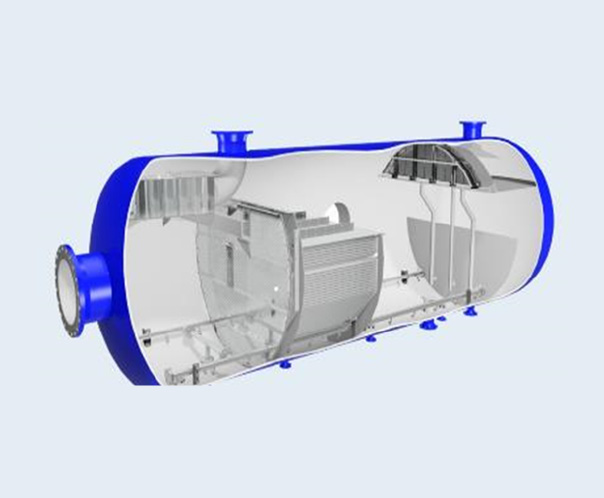

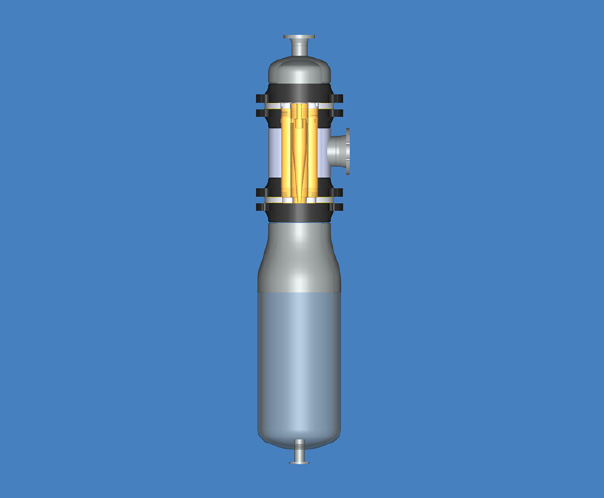

The electrostatic coalescence separation process comprises two principles: dehydration and desalting. In the Technomak technology, the high efficiency inlet distributor injects crude just below or between the electrical grids depending on inlet BS&W.

Between the grids the water droplets will attract each other and as a result, they coalesce, grow in size, and then fall out of the upward flowing crude. The treated crude is collected at the top of the vessel while the effluent water is collected at the bottom.

Technomak offers several coalescence technologies, including the following:

The applications include:

Heater Treater direct or indirect utilises heat and mechanical separation internals such as plate packs, baffles and electrostatic grids to break the crude oil emulsion and achieve up to 0.1 BS&W.

Indirect/direct fired heaters include the following:

The applications include the following:

Gas dehydration is the process of removing water from the gas stream in order to meet pipeline specifications. In addition to separating oil and condensate from the wet gas stream, it is also necessary to remove most of the associated water.

Most of the liquid, free water associated with extracted natural gas, is collected by oil and gas separators. However, additional water vapour removal is often needed with a dehydration unit using solvents like TEG or molecular sieve.

TEG is used to remove water from gas for corrosion or in order to meet sales gas specification.

Technomak provides customised design for the following:

Technomak provides two types of technologies. They are as follows:

For the Amine Unit:

Technomak provides membrane-based nitrogen generation technology:

The nitrogen produced from membrane can be used as stripping gas or as utility in the plant for blanketing, sealing, purging etc.

There is an Environmental Conscience to reduce

Environmental emissions by flare gas. Technomak

bring vast experience in gas treatment technologies

to this segment as well, where the flare gas is

recovered with suitable technologies and benefits

End User on emission control and energy

recovery.

Technomak can evaluate and offer

below technologies as standalone or in combination

for flare gas recovery;

Technomak provides degasser for gas/liquid separation with removal of free and dispersed oil droplets and solid particles from produced water.

It’s often used as the first stage in produced water treatment scheme when there are different source of PW coming from high pressure separators.

Technomak designs and fabricates CPI units that can be quite effective as the primary oil/solids removal device in produced water treatment.

CPI units are designed for either degassed or live process fluids and this affects the mechanical design basis significantly. If CPI units are designed to contain live process liquids, it requires the use of pressure vessels to avoid uncontrolled emissions of hydrocarbon gases or liquids.

CPI units utilise Plate Packs as the primary method of allowing the settling of oil & solids within controlled parameters. The use of Plate Packs is integral to the separation process as they rely on Stokes’ law of settling oil and solids.

Technomak provides deoiling hydrocyclones where the internal geometry of each liner is designed to provide high separation efficiency.

The application includes downstream of a production separator/CPI/degasser /produced water collection vessel.

Technomak provides hydraulically-operated Induced Gas Flotation Units to remove dispersed oil droplets from produced water streams.

HIGF Units separate and recover oil and fine solid particles from water through the creation of fine gas bubbles (typically < 50 microns in diameter), that are dispersed through the incoming produced water.

The applications include Secondary treatment to remove dispersed oil droplets from produced water and waste water streams and Fine suspended solids from produced and waste water streams.

Technomak provides nutshell filter (NSF) to produced water polishing.

Technomak provides three types of NSF depending on process fluids:

A. Nutshell Filter with Scrubber Pump Design

After filtration cycle, the media is cleaned by re-circulating it through the scrubber pump and internal tubular screen. The pump is a proprietary equipment and specifically designed to handle the nut shell media without attrition of media.

Advantage

Robust design for challenging service - like high viscous oil and high inlet OiW and TSS loading.

B. Nutshell Filter with Internal Agitator

After filtration cycle, the media is cleaned by internal mechanical mixer with impeller. Thus the media is not taken outside the vessel.

The Internal mechanical mixer is specifically designed for nut shell media cleaning service without high attrition of media.

Advantage

The advantage is that they consume less power than Scrubber Pump design.

C. Nutshell Filter with Gas Scouring

After filtration cycle, the media is cleaned by scouring with fuel gas or nitrogen.

Advantage

Technomak Desanding Hydrocyclone (Desander) is a fit-for-purpose solid-liquid cyclone designed to remove sand from produced water streams. This technology is most commonly installed on the outlet of a three-phase or FWKO separator.

Designed primarily for water flow streams, the Desander removes sand to protect downstream oil-water separation equipment (deoiling hydrocyclones, CPIs, flotation cells, or media filters) or prevent solids transport to reinjection wells.

The applications include:

Solids settled and accumulated inside the vessel can be flushed out with internal solid flushing arrangement. Conventional or cyclonic type:

This can be installed inside Slug catcher / Separators/ PW Degasser/CPI.

Industrial Wastewater - Main Sources

Sewage Water - Main Sources

Major Impurities/Contaminants in Wastewater

Typical Maximum Limit for Treated Water

Wastewater Treatment Process requires major equipment mentioned below and are offered by Technomak on a turnkey basis:

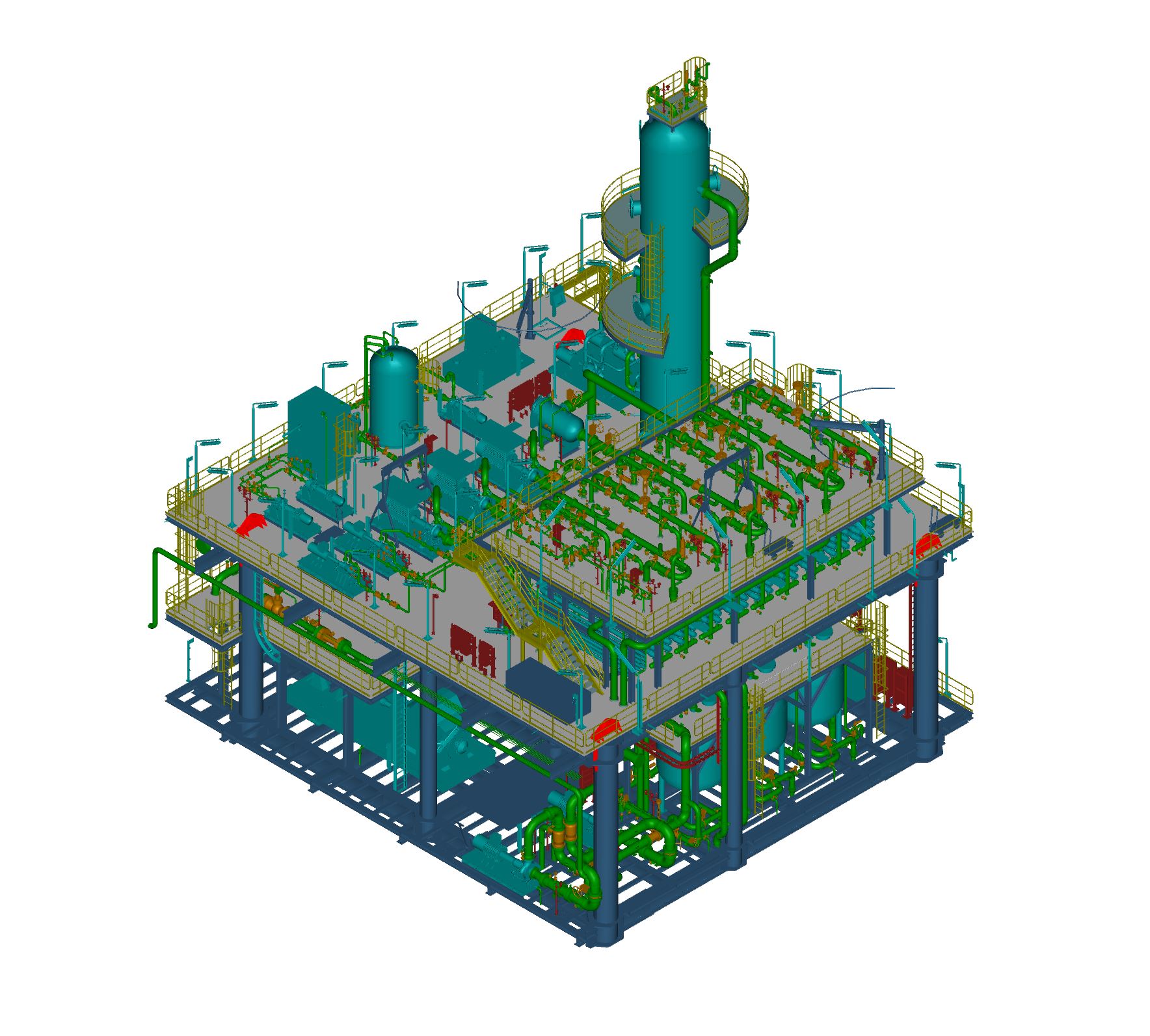

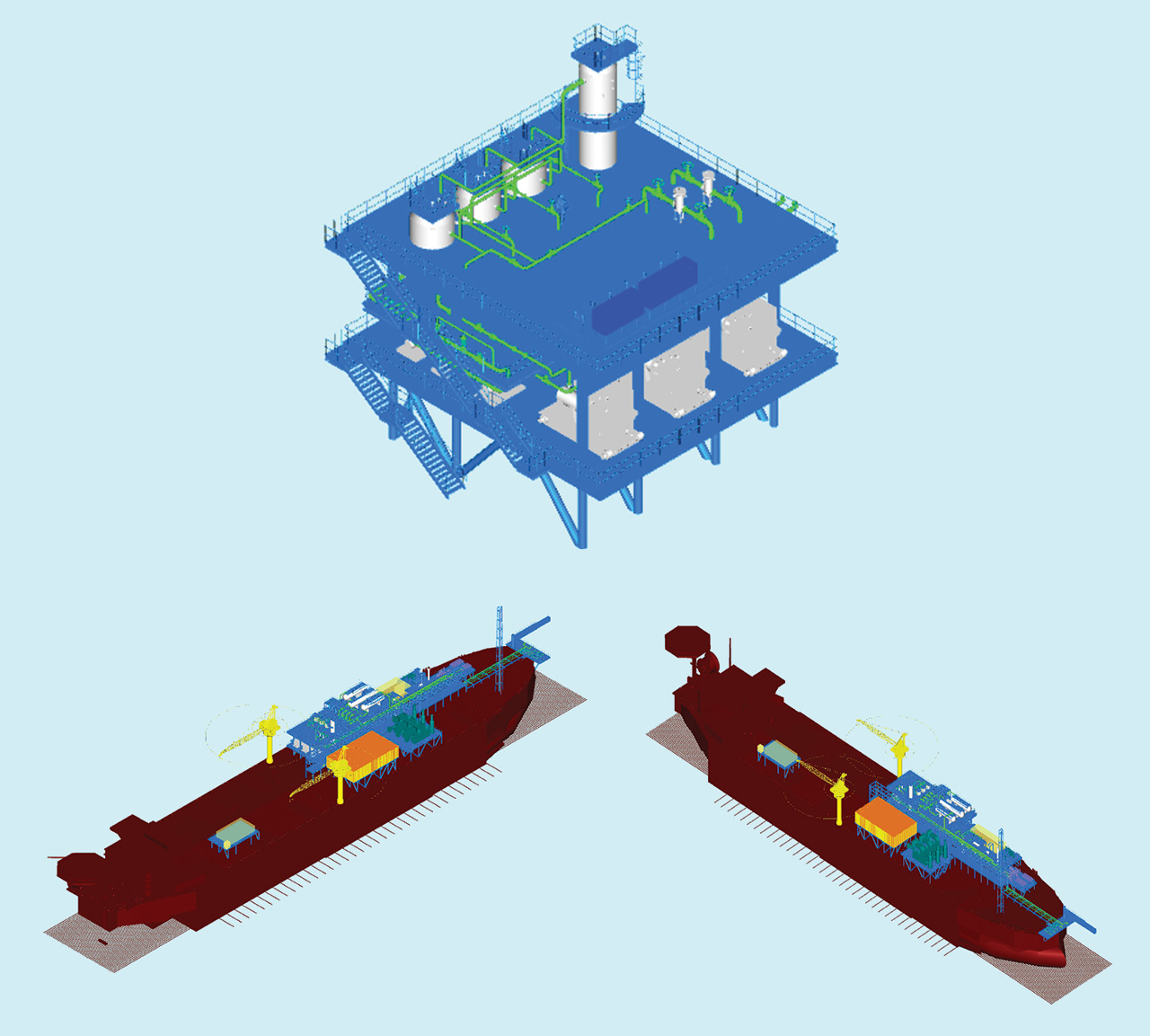

Technomak offers a complete range of Sea Water Treatment technologies to meet the treated water quality suitable for Water Injection wells. These can be supplied as individual skids or as a single complete module for off-shore installation.

For Sea Water Treatment, our offering includes:

We use cookies to personalise content and ads, to provide social media features and to analyse our traffic. Some of these cookies also help improve your user experience on our website, and assist with navigation and your ability to provide feedback. By clicking ‘OK’ below, you consent to the use of these types of cookies. However, some system cookies that are needed for this website to work properly have already been set. Read more in our cookie notice on how to prevent any cookies from being set.